THERMAL INTERFACE MATERIAL

— TAKING THE HEAT OUT OF ELECTRONIC DESIGN —

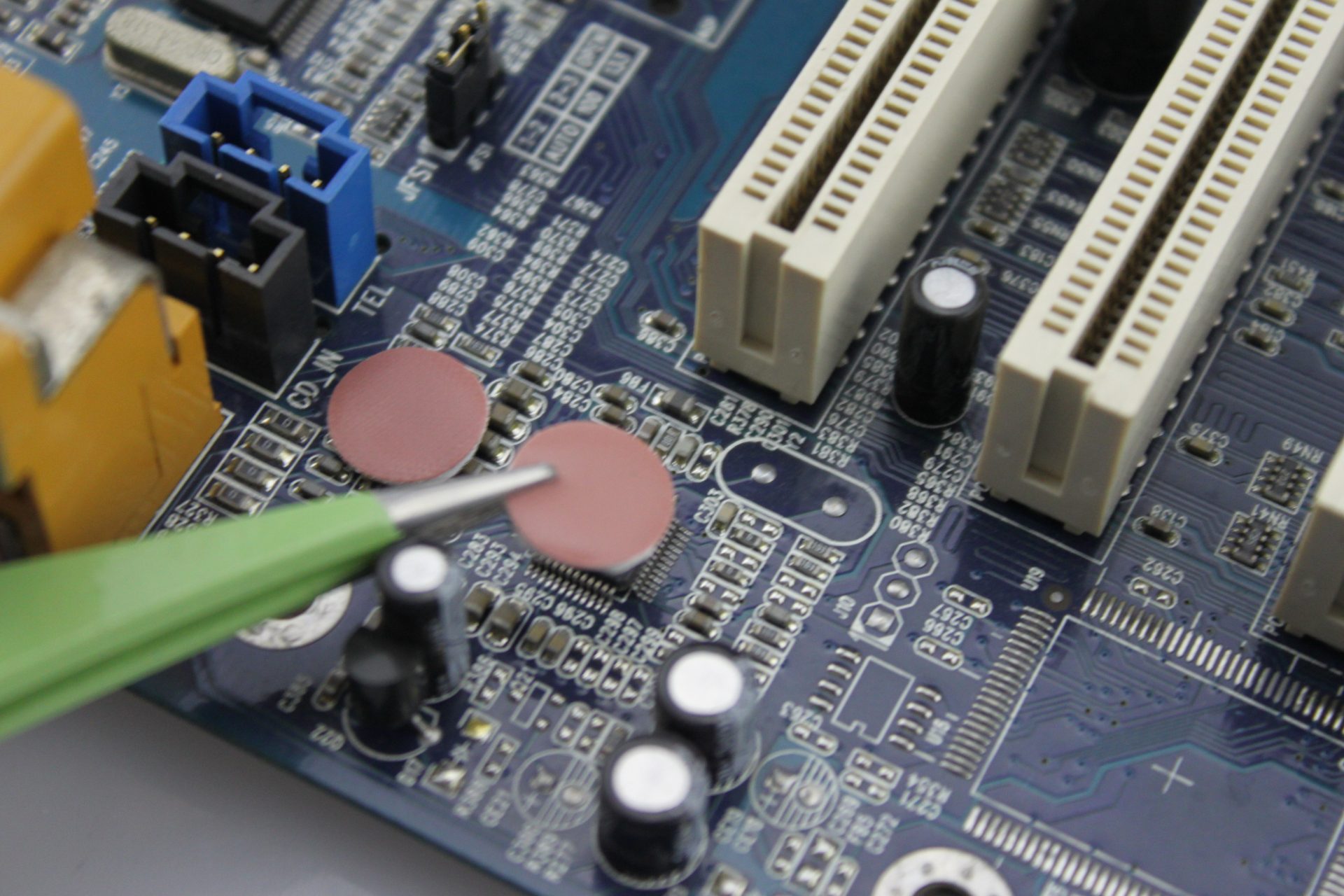

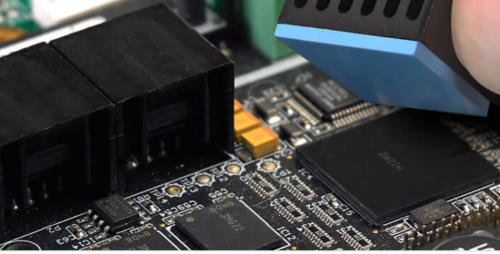

Thermal Interface Material is used to fill air gaps that occur between mating surfaces in electronics. These gaps prevent the fast and effective transfer of heat between component and heat sink.

TAKING THE HEAT OUT OF ELECTRONIC DESIGN – WHY THERMAL INTERFACE MATERIAL IS YOUR ALLY?

The requirement to drive electronic components harder and faster, at higher power, from smaller packages means they are running hotter – and too much heat is a component killer. Thermal Interface Material removes the heat, therefore removing the problem, this protects components from overheating, damage and failure.

THERMAL INTERFACE MATERIAL IS A POWERFUL, COST EFFECTIVE SOLUTION.

Thermal Interface Material (otherwise known as TIM) is at the front-line in the battle to remove heat from electronic components. It is a simple, but very effective solution that significantly improves the transfer of heat from component to heat sink.

LEDs, ELECTRIC VEHICLE MOTOR DRIVES, AUDIO SYSTEMS, AUTOMOTIVE LIGHTING, BRAKING AND STEERING SYSTEMS.

These are all examples of applications where Thermal Interface Material is used as part of effective thermal management to ensure reliability, performance and to prevent component failure.

DISTRIBUTION:

DK Thermal distribute and convert thermal interface material for both Laird and 3M. Offering the complete Laird and 3M ranges which includes Laird’s industry standard T-Gon, T-Gard & T-Flex brands and 3M’s highly acclaimed thermal transfer tapes such as 3M 8940 and 3M 8805.

There are many materials to choose from and correct selection is very much application specific. The five main categories and further information about them is highlighted below:

ELECTRICAL AND THERMALLY CONDUCTIVE INTERFACE PADS

T-gon™ 800 Series is a high performance, cost effective thermal interface material. T-gon™ 800 is used where electrical isolation is not required. Its unique grain-oriented, plate-like structure allows it to conform exactly to surfaces, thus maximizing heat transfer.

T-gon™ 800 can be supplied in 12″ x 18″ (305 mm x 457 mm) or 18″ x 24″ (457 mm x 914 mm) sheets, in rolls, or die cut to specific configurations. T-gon™ 800 is available with proprietary pressure sensitive adhesive on one side. This adhesive coating is the thinnest available, thereby minimizing any impact on thermal performance.

FEATURES & BENEFITS

- High thermal conductivity of 5 W/mK in Z axis and 140 W/mK in the X-Y axis

- Greater than 98% graphite

- Low thermal resistance

- Thicknesses of 0.005″, 0.010″ and 0.020″ (0.125 mm, 0.25 mm, and 0.50 mm)

APPLICATIONS

- Power conversion equipment

- Power supplies

- Large telecommunications switching hardware

- Notebook computers

THERMAL PHASE CHANGE MATERIALS

Thermal phase change materials are solid pads at room temperature that melt at operating temperatures to form an intimate contact on the mating surfaces to produce low thermal resistance. Laird Technologies offers a broad range of phase change materials (PCM) for a variety of applications.

BENEFITS & FEATURES

- Supplied on rolls with top tabbed liners for easy application; clearly superior to thermal grease application

- Provides superior surface wetting, minimum bond-lines thickness and actively expels entrapped air, all leading to the maximum thermal performance of any phase change material available in the market.

- Designed to provide stable and reliable performance

APPLICATIONS

- Microprocessors

- Chipsets

- Graphics processing units

- Custom ASICS

- Power components and modules

- Memory Modules

THERMAL CONDUCTIVE GAP FILLERS

Thermally conductive gap fillers are future generation compliant cooling materials. These Laird thermally conductive gap fillers are the softest and highest thermally conductive gap fillers available (in thicknesses ranging from 0.20 mm to 5.08 mm).

Thermally conductive gap fillers deliver engineers and designers the most dimensionally toleranced materials available. Extreme compliancy reduces component stress while higher thermal conductivity provides thermal performance required for next generation designs.

APPLICATIONS

- Notebook computers

- Handheld microprocessor devices

- Telecommunications hardware

- Semiconductor test equipment

- Servers and desktop computers

- Memory modules

- Mass storage devices

- Power conversion equipment

- Flat panel displays

- Audio and video components

THERMAL CONDUCTIVE ELECTRICALLY INSULATING MATERIALS

Introducing T-gard, a new line of thermally conductive electrically insulating materials, designed to solve over-heating issues for today’s power component assemblies. Most T-gard products are film-based and designed to resist cut through in screw mounting applications. T-gard products provide a more consistent breakdown voltage over other insulation constructions.

The soft conformal coating on the film core provides an excellent mating surface for low pressure clip mounting applications. The T-gard insulator products are available in a diverse range of thermal performances to suit any application.

T-gard materials can be die-cut into any standard or custom shape.

FEATURES & BENEFITS

- Thermal impedance range from 0.13 – 0.6°C-in /watt at 50 psi

- High dielectric strength of >6,000 volts AC

- Resistant to tears and cut through

- UL recognized materials File No. E180840

APPLICATIONS

- AC/DC power supplies

- Audio amplifiers

- Automotive

- Power generators

- UPS

THERMAL TRANSFER TAPES

DK Thermal provide a range of 3M thermal transfer tapes. All of them offer outstanding adhesion and come in a range of thicknesses to suit the most diverse application. These tapes provide unrivalled bonding strength and are designed to have excellent heat dissipating properties. These tapes are commonly used in applications such as heat sink mounting and in the thermal management of LED lighting.

3M thermal transfer tapes provide excellent long term reliability, good electrical insulation and flame retardant

performance.